What do you think about when somebody mentions laser cutting on the Sunshine Coast? Do you think of metal cutting, engraving, sign-making? The fact is, laser cutting covers all that and more. Lasers are proving themselves to be one of the most versatile tools on the planet!

Businesses providing a laser cutting service do vary in the products they produce. For the smaller operator, engraving plaques and trophies might be the extent of their services. However, the bigger businesses, those operating as signage experts, can offer the full gamut of services.

You likely come across their products daily. Next time you visit your doctor, dentist, solicitor or accountant, you’ll probably walk past a laser cut sign. That control panel you use every day at work will be laser engraved. So will the safety signage on that electrical item you just bought. Laser cutting on the Sunshine Coast is everywhere!

Laser Cutting Service

The reason for this is that it offers many advantages and benefits. Versatile enough to be used on almost any material, including leather, fabric, wood, and concrete, it produces dynamic, accurate results that don’t fade with time.

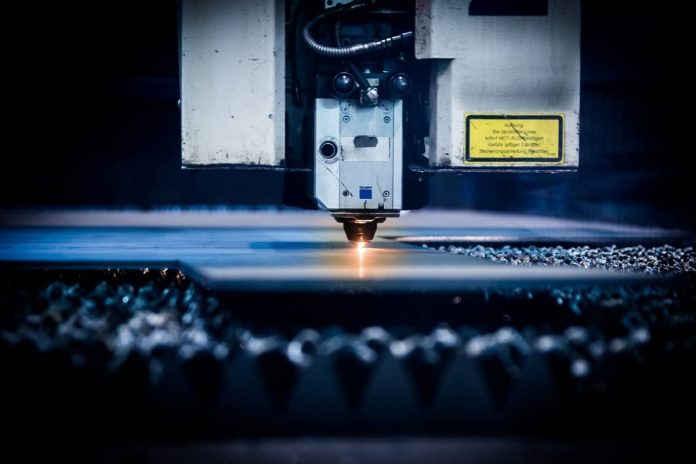

Laser cutting is ideal for all types of plastic and stainless steel, aluminum, acrylic, glass, and much more. It can bring your business signage to life and is very cost-effective. The secret is to choose a laser cutting service that also offers CNC ability.

A CNC laser cutting allows extremely precise and accurate cutting. Best of all, it follows computer templates which, in the hands of a skilled technician, means pretty much anything is possible. It also enables intricate designs to be cut and logos and artwork to be saved for future use.

Laser Cutting Sunshine Coast

CNC cutting is low-cost, which makes it a very affordable option for smaller businesses. And here’s the thing; because of its affordability and precision, CNC cutting is being used for everything from jewelry making to automotive parts. That, in turn, is keeping down the cost of those products for the consumer.

In the automotive industry, laser cutting enables more parts to be made from plastic, reducing the weight of vehicles and wear and tear. Laser cutting is even used to make artificial valves for the human body.

Laser cutting is not new, but its use over the past few decades has rapidly increased. The demand for laser cutting services came about as manufacturing and production processes developed and required faster, cheaper ways of doing things. Who used it extensively in the automotive, aerospace, electronics, and medical industries.

More Affordable

One of its biggest advantages was the fact it’s a non-contact process. That means Who can use it on far more materials without the risk of burning or damage. It’s also more cost-effective for power usage, again making products more affordable for the masses.

Laser cutting is safer than many other methods, which is a big advantage for workplace health and safety. And it creates less waste, making it more environmentally friendly.

Another plus is that you require fewer tools; one laser can be used for several different applications, such as engraving, cutting and drilling. And, as it reduces the need for machining, parts can be moved on quickly to the next production stage, again saving time and money.

When you choose a company experienced in laser cutting on the Sunshine Coast, skilled technicians will be able to offer you plenty of options and advice. They need an idea of your requirements and your budget to find the perfect solution.

Outstanding Signage

Laser cutting is one of the most widely used manufacturing processes in the world. It can easily cut steel, aluminum, nickel, brass, tungsten, and more when it comes to metal. The thickness of the metal isn’t an issue, as lasers can cut parts for everything from trucks to mobile phones.

What you might not realize is that the laser cutting service can be used for ceramics, too. We’re not talking about your coffee mug here, rather the ceramic parts used in industry due to its electrical insulation and thermal conductivity.

When it comes to signage, the options are endless. CNC cutting can create architectural signs that stand out, with 3D rendering, engraving and polished edges.

This type of signage is cost-effective and, compared to painted signs, it is much tougher, longer-lasting and weather-resistant. In addition, you won’t need to worry about your sign chipping or fading, as it will remain prominent and easy to read for a long time.

Using marine-grade stainless steel will also make your signage more resistant to salt air damage, a very useful feature on the Sunshine Coast.

Read More:- Surprising Items In Your Kitchen That Are Full Of Germs