Self-priming pumps are centrifugal pumps designed to allow the pumping of liquids containing air or gas, without losing pumping capacity. This type of hose pump has multiple applications for the suction of wastewater, agriculture, or the food industry, chemical, pharmaceutical. Its self-priming system allows it to operate without vacuum pumps, foot valves, or additional pipes.

Volumetric hydraulic pumps and self-priming pumps

These hose pumps fall within the category of hydraulic pumps. According to its operating principle, we can differentiate between volumetric hydraulic pumps, such as reciprocating piston pumps or rotary volumetric pumps. Within this last category are peristaltic pumps, widely used for industrial use. These self-priming industrial pumps offer variable flow rates, so it is always advisable to consult with your hose pump manufacturer on the specifications required, taking into account the type of work to be performed.

The second type of hydraulic pumps is rotodynamic pumps, which in turn are classified into radial or centrifugal, rotary, axial, diagonal, or helio centrifugal pumps. Self-priming pumps belong to the first category, centrifugal pumps. Self-priming centrifugal pumps are characterized by a greater power than conventional centrifugal pumps. This quality makes these self-priming pumps suitable for the suction of water at great depths, with many applications for the domestic water supply, waste and sandy water suction, quarry water or irrigation systems for agriculture.

Self-priming pumps: how do they work?

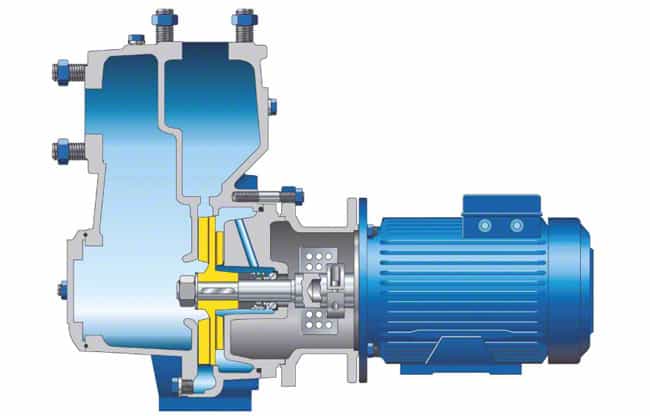

Centrifugal or rotary pumps are composed of an impeller fixed to a rotary shaft and a housing, with input and connection of discharges. To work, the rotating vane rotor must be immersed in liquid. When moving, the vanes drag in liquid to their ends at high pressure. The rotor also provides liquid at high speed, which can be transformed into pressure in the diffuser. The high-pressure industrial pumps have several rotors in series with rear diffusers to each rotor and guide fins to reduce the speed of the liquid. Finally, these self-priming pumps also have a valve in the outlet duct, which allows controlling both the flow and the working pressure.

Advantages of self-priming pumps

- These hose pumps are high-performance equipment, prepared to operate in extreme conditions. To ensure a long service life, it is recommended that you have a robust design housing with mechanical seals.

- Self-priming pumps allow evacuating large flow rates, up to 35,000 rpm, which can contain suspended solids of up to 3 inches in spherical diameter.

These pumps offer a constant and high flow, with many applications. They are recommended for high flow rates and low pressures. - Its maintenance is very simple, with easy access to the inside of the pump. In addition, when placed on the surface they can also be repaired very easily in case of failure.

- Self-priming pumps stand out for their reliability, capable of maintaining continuous work 24 hours a day, 365 days a year.

As you see, these hose pumps can bring you important advantages. If you have doubts about the technical specifications you need or the most appropriate model for your activity, it will be very useful to have the advice of a hose pump manufacturer, which can help you choose the optimal solution, according to your needs.